Differential thermal analysis (DTA) is a technique for measuring the relationship between temperature difference and temperature between material and reference material under programmed temperature control. Differential thermal analysis (DTA) curve describes the relationship between temperature (T) and time. In DTA test, the change of sample temperature is caused by the endothermic or exothermic effect of phase transition or reaction. Such as: phase transformation, melting, crystalline structure transformation, boiling, sublimation, evaporation, dehydrogenation reaction, fracture or decomposition reaction, oxidation or reduction reaction, lattice structure destruction and other chemical reactions.

Brand: Jiuban

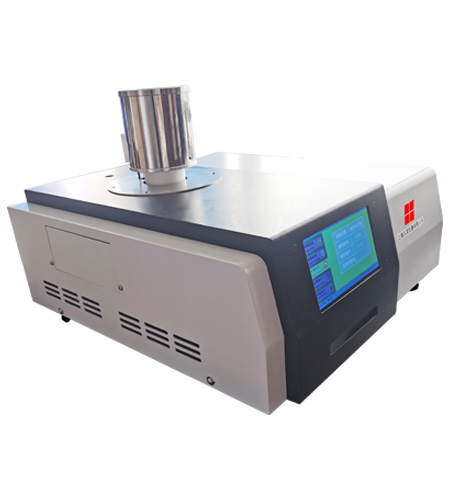

Model: JB-DTA-1150

Name: Differential thermal analyzer

一、Product Overview:

Differential thermal analysis (DTA) is a technique for measuring the relationship between temperature difference and temperature between material and reference material under programmed temperature control. Differential thermal analysis (DTA) curve describes the relationship between temperature (T) and time. In DTA test, the change of sample temperature is caused by the endothermic or exothermic effect of phase transition or reaction. Such as: phase transformation, melting, crystalline structure transformation, boiling, sublimation, evaporation, dehydrogenation reaction, fracture or decomposition reaction, oxidation or reduction reaction, lattice structure destruction and other chemical reactions.

二、Technical parameters:

1. Temperature range: room temperature to 1150℃

2. Range range: 0 ~+2000 uV

3. DTA Accuracy: 0.01 UV

4. Heating rate: 1-80 C/min

5. Temperature Resolution: 0.1 C

6. Temperature Accuracy: +0.1 C

7. Temperature repeatability: +0.1 C

8. Temperature Control: Temperature Increase: Program Control can adjust parameters according to need

Cooling: Air Cooling Program Control

Constant Temperature: Program Control Constant Temperature Time Arbitrary Setting

9. Furnace body structure: Furnace body adopts upper open cover structure instead of traditional lifting furnace body, which has high accuracy and is easy to operate.

10. Atmosphere Control: Automatic Switching of Internal Procedures

11. Data Interface: Standard USB Interface Matching Data Line and Operating Software

12. Display mode: 24 bit color 7 inch LCD touch screen display

13. Parameter Standard: It is equipped with standard material and has one-button calibration function. The user can calibrate the temperature by himself.

14. Baseline adjustment: Users can adjust baselines through baseline slope and intercept

15. Working power supply: AC 220V 50Hz

[Differential Thermal Analysis Heating Furnace]

★ The furnace is made of 1kW Fe-Cr-Al wire bidirectional winding, eliminating the effect of the magnetic field generated by the furnace wire on the test results of the sample, and has a long heating constant temperature zone.

[Differential Thermal Analysis Temperature Controller]

★ Using the regulator to control the input voltage of the furnace wire, the heating process is heated up or cooled at a certain rate, and the temperature is constant.

三、Main features:

★ The instrument master chip uses the Cortex-M3 kernel ARM controller, which has a faster processing speed and more accurate temperature control.

★ Using USB two-way communication, the operation is more convenient.

★ With a 7-inch 24-bit color full-color LCD touch screen, the interface is more friendly.

★ The nickel Chromium alloy sensor is used to resist high temperature, corrosion resistance, and oxidation resistance.